PRODUCT CENTER

Y46 series

- Product introduction

Y46 series (mobile and rotary frame hydraulic press)

●The gantry frame structure can realize high-precision forming and processing of plates, profiles and components.

● The movable design of the indenter and worktable can provide more diversified and personalized forming angles and curves.

● Equipped with two sets of automatic lifting rollers, which can realize the lifting and feeding of the processed plates, and can also be used for the rapid replacement of the mold.

● Touch-type CNC system is simple and easy to use, and is equipped with a handheld remote control, which makes the operation more arbitrary.

● Small footprint, large pressing width, and high cost performance.

The hydraulic press is one of the important processing equipment in the hull workshop of the repair plant. It can realize various process operations such as bending forming of plates, profiles and components by means of various molds. This machine is mainly used for bending processing of steel plates and pressing grooves. Other parts.

This machine is a mobile rotary head gantry hydraulic press. It is different from the conventional C-shaped press and four-column press. In addition to the main cylinder can do up and down movement, the upper head and the lower worktable can move left and right at the same time or separately. Anti-movement, due to these functions, it has perfect process performance and is widely used by the shipbuilding industry at home and abroad.

This hydraulic press has the function of moving and rotating the indenter and the workbench, so when pressing, bending, and correcting the plates of various switches, as long as the indenter and the worktable are adjusted to the required processing position and angle, the workpiece can be processed , Replace the heavy manual labor of manual moving work with the function of the press, not only can greatly reduce the labor of workers

Strength, and further improve the process performance of the equipment itself, thereby improving the processing accuracy and production efficiency of the press.

Because the hydraulic press has the functions of moving and rotating, compared with the frame type hydraulic press with the same internal net width, this press has twice the pressing width than the conventional press, which can reduce the floor space of the workshop and save investment.

The hydraulic press is provided with two sets of lifting rollers at the front and back, which can realize the lifting and feeding of the processed plates, which improves the continuity and automation of the operation process of the hydraulic press. The use of lifting rollers when changing the mold can improve the efficiency of mold change.

The electrical control system of this machine is controlled by PLC, human-machine interface touch operation terminal, absolute encoder, industrial field bus I/O module, etc. The digital display of stroke and rotation angle, lifting roller table and hydraulic press are on the same operating platform Unified operation, and there is no handheld remote control.

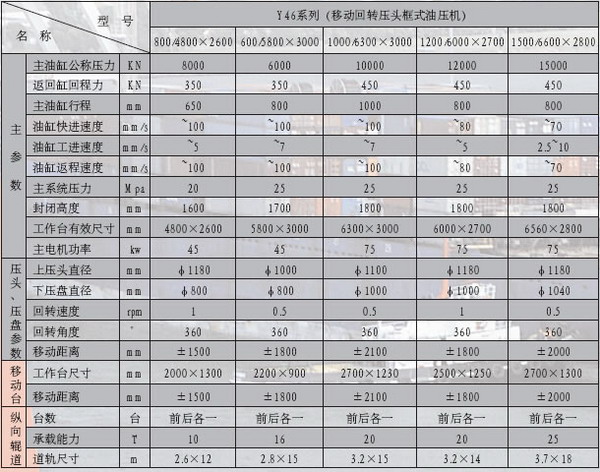

Product parameters:

Hubei Tri-Ring Metalforming Equipment Co.,Ltd

Founded in 1958, Hubei Sanhuan Forging Equipment Co., Ltd. (Huangshi Forging Machine Tool Company) won the "China's Leading Enterprise in Metal Forming Machine Tool Manufacturing". After 50 years of innovative development, it has gradually grown into a world-leading scientific research capability and manufacturing level. Modern enterprise. The company has 750 employees, including 108 engineering and technical personnel, and more than 30 senior technical experts. It is a postdoctoral industrial base in Hubei Province. It has a research and development base with an annual output of 1,500 sets of precision CNC forging machine tools. The company's products have won "Chinese famous brand products" , "China Machinery Industry Science and Technology First Prize", "National Science and Technology Progress Second Prize" and a series of honorary titles.

750people

Existing employees

60year

The company has been established

1500set

Annual output of precision CNC forging machine

108people

engineer

Relevant recommendations

MESSAGES

WRITE A MESSAGE TO US