PRODUCT CENTER

Impuls series laser cutting machine

- Product introduction

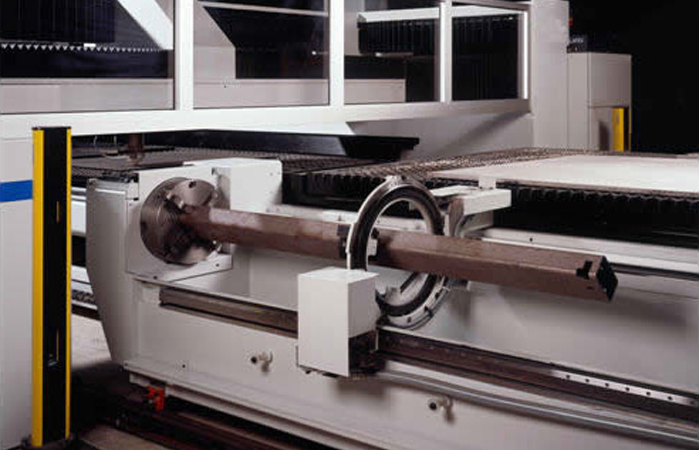

1. Impuls 4020R model

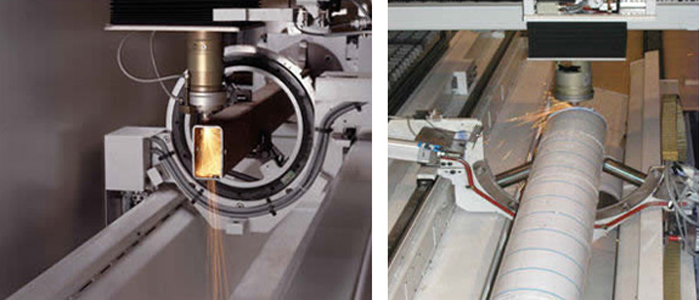

Flexible processing for flat sheets, shaped workpieces and tube profiles

It is a machine tool combined with plane cutting and rotary axis cutting, which obtains a high degree of processing flexibility

Can cut sheets up to 4000 x 2000 mm

The standard configuration includes two plane exchange tables and a fully programmed Z axis with a diameter of 280 mm. The Z axis can be used to process rotating or shaped workpieces

The exchange worktable allows loading and unloading of another worktable while processing one worktable, or loading and unloading operation while cutting shaped parts

When configuring the rotating shaft or the upper and lower material tube profiles, the cutting operation on the flat table can be carried out as usual

The conversion between the flat table and the rotary axis can be completed in seconds

The maximum diameter of the square or round tube that can be processed is 500 mm, and the maximum weight of the shaped workpiece that can be processed is 950 kg

The rotation axis will automatically enter the cutting area to facilitate the conversion between plane cutting and rotary cutting

Fanuc's CNC system, laser source and motor drive are integrated into the LVD machine tool

Important options:

Plasma monitoring system

Feeding system

NC focus

Provide 4kW or 6kW laser source

CADMAN-L 3D offline programming software

Available models:

Pulse 4020R

Product parameters:

Main technical parameters of IMPULS 4020 R laser CNC cutting machinemachine toolbiggest size4000×2000 mmstrokeX axis3150 mmY axis4070 mmZ axis280 mmMaximum nozzle diameter500 mmMaximum tube length4000 mmMaximum positioning speedX axis60 m/min (m/min)Y axis60 m/min (m/min)Z axis150 m/min (m/min)XY axis linkage85 m/min (m/min)Repeatability±0.025 mmpositioning accuracy±0.05 mmMachine size14000×8700×3100 mmSheet metal processing capacity4 kw6 kwCarbon plate20 mm25 mmstainless steel15 mm20 mmaluminum10 mm15 mm2. Impuls 40(30) series

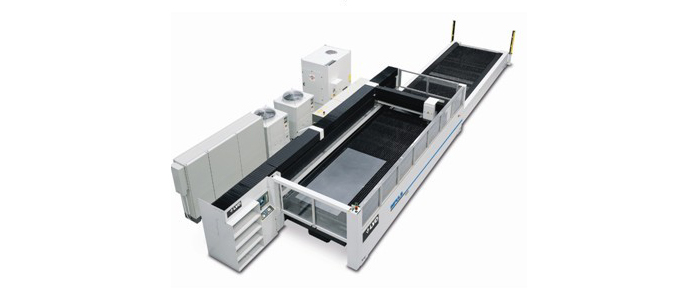

Heavy-duty sheet metal processing

This heavy-duty laser cutting machine is designed to meet the needs of sheet metal manufacturing, sheet metal service centers and other fields that require heavy-duty processing

The width of the worktable can reach 3 meters

Constant laser beam length system ensures stable cutting across the entire processing area

For the processing of multiple sheets, up to 16 sheets of 3m x 1.5m can be placed on the workbench, which prolongs the processing time but shortens the operation time of loading and unloading each sheet

Processing of flat panels can cut medium carbon steel up to 25 mm thick, aluminum 15 mm and stainless steel 20 mm

The Z axis can reach a maximum of 280 mm to cut the shaped workpiece

The application of a constant beam length axis can achieve ideal cutting results

Fanuc's CNC system, laser source and motor drive are integrated into the LVD machine tool

Key options:

Plasma monitoring system

Provide 4kW, 5kW or 6kW laser source

CADMAN-L 3D offline programming software

Available models:

Impulse 6530

Impulse 8030

Impulse 12530

Main technical parameters of IMPULS 4030, 6530, 8030~12530 laser numerical control cutting machineMachine tool (large specification exchange table)

Machine modelImpulse

4030Impulse

6530Impulse

8030Impulse

12530Sheet sizeL Length (mm)40006500800012500W width (mm)3100310031003100Workpiece weight (kg)2400390048007600Shaft travelX axis3150315031503150Y axis4070407040704070Z axis280280280280Maximum positioning speedX axis60 m/min (m/min)Y axis60 m/min (m/min)XY linkage85 m/min (m/min)Z axis150 m/min (m/min)Repeatability±0.025 mmpositioning accuracy±0.05 mmMachine sizeL Length (mm)16000190002200030000W width (mm)8700870087008700H height (mm)3300330033003300Sheet metal processing capacity4kw5kw6kwCarbon plate20mm25mm25mmstainless steel15mm15mm20mmaluminum10mm12mm15mmImpuls 4020 series bird's eye view

Impuls 6020 series

Powerful laser cutting machine for heavy-duty machining

Set flexibility, easy operation and high performance in one

Ideal machine tool for heavy-duty machining, the largest sheet size that can be processed is 6000 x 2000 mm

Processing of flat panels can cut medium carbon steel up to 25 mm thick, aluminum 15 mm and stainless steel 20 mm

NC focus control for fast switching time and optimized cutting

The standard configuration contains two plane exchange tables, allowing the machine tool to process the workpiece on one table while the operator can load and unload on the other table

The specific beam length constant system eliminates the laser beam offset, guarantees the same cutting result across the entire table range, and excellent edge cutting quality at the optimized speed

Fanuc's CNC system, laser source and motor drive are integrated into the LVD machine tool

Key options:

Plasma monitoring system

Provide 4kW or 6kW laser source

CADMAN-L 3D offline programming software

Available models:

Impulse 6020

Impuls 6020 series bird's eye view

Main technical parameters of IMPULS 6020 R laser CNC cutting machine

Main technical parameters of IMPULS 6020 R laser CNC cutting machinemachine tool

biggest size6200×2050 mmTravel: X axis6280 mmY axis2100 mmZ axis280 mmMaximum weight of workpiece2500 kgMachine weight27000 kgMaximum positioning speedX axis60 m/min (m/min)Y axis60 m/min (m/min)Z axis150 m/min (m/min)XY axis linkage85 m/min (m/min)Repeatability±0.025 mmpositioning accuracy±0.05 mmMachine size17000×8700×3100 mmSheet metal processing capacity4 kw6 kwCarbon plate20 mm25 mmstainless steel15 mm20 mmaluminum10 mm15 mm

Laser generator

Type: FANUC --HF fast axial carbon dioxide laser

Hubei Tri-Ring Metalforming Equipment Co.,Ltd

Founded in 1958, Hubei Sanhuan Forging Equipment Co., Ltd. (Huangshi Forging Machine Tool Company) won the "China's Leading Enterprise in Metal Forming Machine Tool Manufacturing". After 50 years of innovative development, it has gradually grown into a world-leading scientific research capability and manufacturing level. Modern enterprise. The company has 750 employees, including 108 engineering and technical personnel, and more than 30 senior technical experts. It is a postdoctoral industrial base in Hubei Province. It has a research and development base with an annual output of 1,500 sets of precision CNC forging machine tools. The company's products have won "Chinese famous brand products" , "China Machinery Industry Science and Technology First Prize", "National Science and Technology Progress Second Prize" and a series of honorary titles.

750people

Existing employees

60year

The company has been established

1500set

Annual output of precision CNC forging machine

108people

engineer

Relevant recommendations

MESSAGES

WRITE A MESSAGE TO US