PRODUCT CENTER

V series CNC turret punch press

- Product introduction

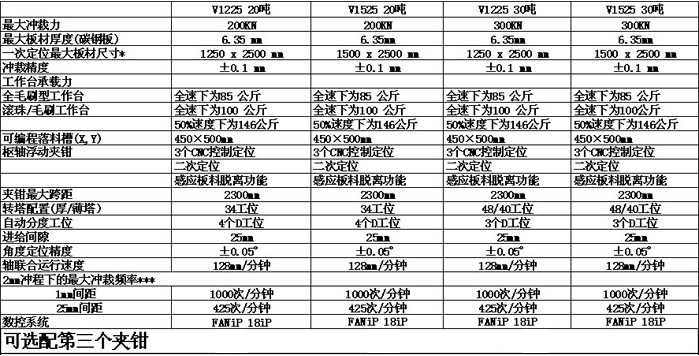

Fully equipped 20-ton or 30-ton CNC CNC turret punch press

It is the most ideal model for mass production and processing

Rugged fully configured machine

High-performance 20-ton or 30-ton hydraulic system

Large and flexible 48-station or 34-station thick turret configuration

Up to 4 self-indexing stations of 88,9 mm (3 are standard)

The maximum thickness of the sheet that can be punched is 6.4 mm

114.3 mm station can be selected as an option on the 30-ton series

25mm feed gap maximizes forming ability

Quick die change system

'Self-indexing' multi-submode function (LVD's patented product)

100% programmable punch system with forming and noise-free punching functions

'Wheel Die' and'Thread' Die are also compatible

Smart Stroke? Automatically optimize punch stroke

3 standard working clamps programmable and repositionable

Smartclamp? can automatically optimize the blanking process in the dead zone

450 x 500 mm blanking chute

The powerful, "easy to operate" Fanuc 180iP CNC system developed on the basis of Windows® PC has a network card function

Key options:

ABS tool automatic lubrication

Brush/ball hybrid table

Automatic loading and unloading system

Manipulator automatic material extraction and sorting system

CADMAN-P 3D offline programming software

Available models:

V-series: V1212 / 20 tons processing range 1250 x 1250 mm (in case of one-time positioning)

V1225 / 20 tons processing range 1250 x 2500 mm (in case of one-time positioning)

V1212 / 30 tons processing range 1250 x 1250 mm (in case of one-time positioning)

V1225 / 30 tons processing range 1250 x 2500 mm (in case of one-time positioning)

Automatic loading and unloading system

Compared with manual operation, it can reduce the sheet operation time by at least 80%

Increased production volume and achieved unmanned production

S-series and V-series CNC turret punch press can be equipped with automatic loading and unloading system

Can be retrofitted

Workable sheets up to 1524 x 3048 mm

Compared with other sheet material operation systems, this automatic loading and unloading system is more compact and compact

Equipped with a full-brush type table to reduce noise and scratches on the workpiece

Can handle fine workpieces that are well arranged

Automatic alarms and task screens can be provided as options, which can be used to remind the operator when the machine tool cannot run normally or the operation is forced to stop

Available models:

Automatic feeding 1225 Maximum sheet 1250 x 2500 mm

Automatic feeding 1525 Maximum sheet 1525 x 2500 mm

Front view of automatic loading

Manipulator sheet extraction and sorting operation system

With this automation system, the V-series CNC turret punch press can be transformed into an independent punching machining center

Automatic loading, extraction and sorting of sheets and workpieces

Maximize the production capacity of machine tools

The largest sheet size that can be automatically operated is 1524 x 3048 mm

Automatically unload and stack the final product, the smallest stacked workpiece size is 400 x 160 mm

Sturdy sorting robot ensures the sorting operation of high-quality workpieces

The maximum workable weight is 75 kg

Very high integration and control of operating data

Flexible,'configurable' material handling options

Available models:

PickSort 1225 max sheet 1250 x 2500 mm

PickSort 1525 max sheet 1525 x 2500 mm

Front view of robotic sheet extraction and sorting

Hubei Tri-Ring Metalforming Equipment Co.,Ltd

Founded in 1958, Hubei Sanhuan Forging Equipment Co., Ltd. (Huangshi Forging Machine Tool Company) won the "China's Leading Enterprise in Metal Forming Machine Tool Manufacturing". After 50 years of innovative development, it has gradually grown into a world-leading scientific research capability and manufacturing level. Modern enterprise. The company has 750 employees, including 108 engineering and technical personnel, and more than 30 senior technical experts. It is a postdoctoral industrial base in Hubei Province. It has a research and development base with an annual output of 1,500 sets of precision CNC forging machine tools. The company's products have won "Chinese famous brand products" , "China Machinery Industry Science and Technology First Prize", "National Science and Technology Progress Second Prize" and a series of honorary titles.

750people

Existing employees

60year

The company has been established

1500set

Annual output of precision CNC forging machine

108people

engineer

Relevant recommendations

MESSAGES

WRITE A MESSAGE TO US